There are around 150,000 words in the English language. There is a story behind each one.

This is the story of the word riveted.

When you’re riveted to something and unable to tear yourself away, there’s a reason you use that word. Riveting two objects together – usually two metal objects – is a simple way to create an almost permanent attachment. The objects literally cannot be torn away from each other – just like you and your TV while you’re binging on the latest Netflix hit.

Riveting is used in all manner of construction. Today, metal is the most commonly riveted material. But wood, clay, and even fabric can be riveted. It’s a simple process:

- Drill a hole through the two things you want to attach.

- Slip the rivet – a small, mushroom-shaped piece of metal – through the hole.

- Hammer the stem side of the rivet while holding the rounded end tightly.

Under the force of the hammer, the stem collapses and pinches the two pieces together.

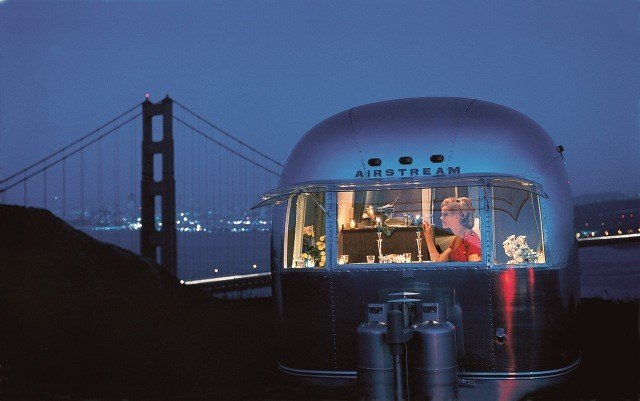

Not much to it. But the result is one of the strongest, most permanent methods of attachment. That’s why rivets have always been the fastener of choice in the construction of every Airstream Travel Trailer in Jackson Center, Ohio.

The story of the rivet is a fascinating trip through history. Here are 25 facts about rivets you may not know:

- The first rivets appeared in Ancient Egypt over 5,000 years ago, where they fixed handles to clay jars.

- By the time of the Ancient Romans, rivets were commonplace in construction.

- Seventh-century Vikings used rivets to attach the planks of their longboats.

- By the mid-19th century, advances in metal technology signaled the dawn of the modern riveting era. Riveting became the primary method for constructing metal tools, buildings, and vehicles.

- Wrought iron, steel, and aluminum are the most common riveted metals because of their relatively soft composition.

- Cast iron is impossible to rivet because it is so inflexible.

- Bolts and welding are two other ways to attach metal together, and each has its use. Bolts are more versatile because they can be disassembled. Welding is more efficient, lighter, and versatile because it can attach a variety of shapes in many configurations. The downside to welding is that it affects the cellular structure of the metals being joined, and can create unwanted internal stress. Riveted joints are more flexible and give under changes in temperature.

- The first common, modern application of the rivet was in boiler making.

- The ship-building industry owes much of its early success to the process of riveting. Huge increases in maritime traffic between 1830 and 1940 boosted the use of the rivet.

- There are two types of riveting: hot and cold. Cold riveting is used most often when small rivets are required (such as in an Airstream travel trailer). Hot rivets are typically larger, and used in large-scale construction like ships, boilers, and steam engines. These rivets are heated red-hot before installation.

- By the mid-1800s rivets were being used in the construction of architectural buildings. Iron beams were riveted together, creating super-strong structures and paving the way for the skyscrapers of today.

- Art and architecture utilized the rivet nearly as much as industry did. At the time of its construction in 1887, the Eiffel Tower in Paris was the tallest structure in the world. At 1,063 feet tall, the tower was formed by 18,038 pieces riveted together with 2.5 million rivets.

- Other notable uses of rivets throughout history include the Golden Gate Bridge (1.2 million rivets), the Sydney Harbor Bridge (6 million rivets), and the RMS Titanic (3 million rivets).

- Rosie the Riveter was a popular, cultural icon of World War II. When millions of men went off to fight, factories began employing women to help with the war effort. Rosie the Riveter became a symbol of feminism, as more and more women worked to construct military equipment and aircraft.

- On May 20, 1873, Levi Strauss secured a patent for his denim jeans with copper rivets. The rivets were meant to reinforce the pants at common stress points. To date, Levis has sold more than 200 million pairs of copper-riveted jeans.

- Many World War II era tanks were riveted together, until weaknesses were found in that method of construction. Evidence from the field of battle demonstrated that the rivets could come loose if a large projectile hit the tank. The loose rivets would become small projectiles themselves, careening around inside the tank and causing injury to the soldiers.

- Some drummers use special sizzle cymbals, which differ from regular cymbals in that they have several rivets attached to them. When struck, a sizzle cymbal’s sound is louder and sharper.

- Ancient techniques for installing rivets utilized a hammer struck against a specialized tool called a bouterolle. This cup-shaped tool would help form the hammered end of the rivet into a mushroom-shape identical to the other end.

- At the Airstream plant in Jackson Center, Ohio, two-person riveting teams work in a delicate, coordinated dance. One person works on the outside of the aluminum shell, one on the inside. Then, one by one they move down the length of the drilled holes setting and hammering the rivets. If you’re interested in seeing this process in action, consider visiting the Airstream plant and taking one of our famous Airstream Factory Tours.

- The advent of pneumatic tools made riveting more efficient. Today’s riveting process is done with special air-powered riveting guns that fire many times a second, hammering the rivet head into its final, mushroom shape.

- Every Airstream Travel Trailer has an average of 3,000 rivets in the walls, trim, and even some of the interior fixtures.

- There are many different kinds of modern rivets. The rivets that attach the aluminum panels of an Airstream body together are called buck rivets, named after the “bucking” process that shapes the head.

- Buck rivets are stout little fasteners, about a half an inch long before they are flattened in the attachment process.

- Pop rivets are also known as blind rivets because one person can easily install them. Instead of hammering the rivet, a special riveting tool pulls the inside section flat.

- The word “rivet” has its origins in Middle English and Old French, from the word “river” which meant to fix or clinch something.

Searching for more #Riveting stories from Airstream? Check out our blog.